Laboratory Facilities

The Department of Mechanical Engineering is a full-fledged department with an intake of 120 students in under graduate course (B.E in Mechanical Engineering) and an intake of 18 in each specialization of post graduation in Industrial Automation and Robotics, and Thermal Power Engineering respectively. The department offers Ph.D / M.Sc (Engineering) under VTU research center. The department consists of Well-equipped, Extensive laboratory and Workshop facilities. It has even procured a CNC turning center and a 5-axis pick and place Robot with all the necessary softwares, in addition to the university prescribed equipment. The department has qualified and experienced faculty to cater to the needs of the students. The department library consists more than 1200 volumes which covers all latest reference books and text books.

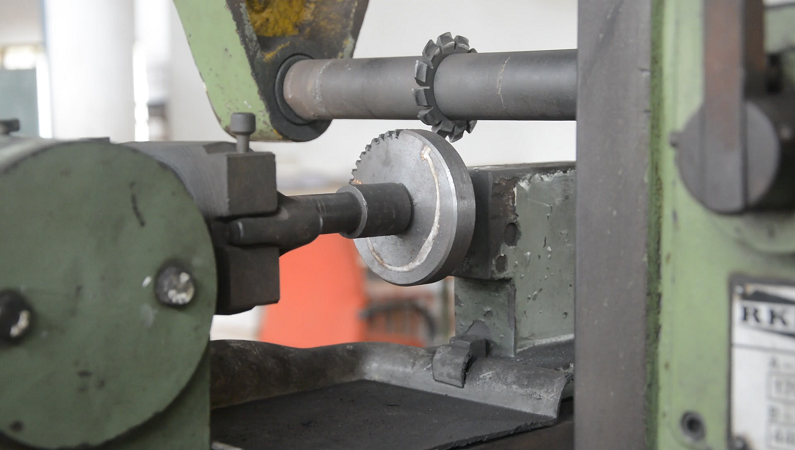

Machine shop:

-

1Lathes, Milling Machines, Drilling Machines, Planing Machines, Power Hacksaw, Grinding Machines, CNC Lathe, Cylindrical Grinding Machine, Bench grinder, Shaping Machine, Surface Grinder.

Foundry & Forging Lab:

-

2Universal Sand Testing Machine, Sand rammer, Beam balance, Permeability tester, Sieve analyser, Clay content tester, Moisture content testing machine, Ovens, Furnace, Different types of Patterns, Moulding boxes, Power Press.

Heat Transfer Lab:

-

3Forced convection apparatus, Pin fin apparatus, Free or Natural convection apparatus, Parallel flow & Counter flow heat exchangers, Thermal conductivity apparatus, Stefan Boltzman apparatus, Emissivity apparatus, Equipment for critical heat flux mesurement, Vapour compression refrigeration apparatus, Air conditioning apparatus.

Design Lab:

-

4Gyroscopic set – up, Journal bearing test rig, Polariscope, Projector for 3D photoelastic analysis, Equipment for studying whirling of shaft, Static and Dynamic Balancing Machine, Porter Governor and Hartnell Governor, Pressure variation measurement equipment, Torque measurement equipment, Equipment for study of kinematics of gear teeth, Inversion and friction of 4 bar mechanism, strain rosettes.

Metallography & Materials Testing Lab:

-

5Brinell, Vickers, Rockwell hardness testers, Magnetic Particle Tester, Impact tester, Rotary fatigue tester, Torsion tester, Universal testing Machine (manual and computer operated), Wear tester, Micro hardness tester, Microscope, Heating Furnace.

Energy conversion Engineering Lab:

-

6Bomb Calorimeter, Junkers Calorimeter, Cleaveland Flash & Fire Point Apparatus, Abel’s flash and fire point apparatus, Pensky Martin flash and fire point apparatus, Redwood viscometer, Say bolt viscometer, Torsion viscometer, Kirloskar water cooled 4-Stroke diesel engine, 2-Stroke Petrol Engine, Variable compression engine, Multi-cylinder Petrol engine (Morse test), Planimeter, Cut-section of 4-Stroke and 2-Stroke engine.

Fluid Machinery Lab:

-

7Francis turbine test rig, Kaplan turbine test rig, Pelton wheel test rig, Gear Pump test rig, Impact of jet on vane test rig, Friction in pipes test rig, Single stage centrifugal pump test rig, Multi stage centrifugal pump test rig, V-notch, Venturimeter, Orificemeter,Air Compressor

Basic Workshop:

-

8Bench vices, Funnel Stake, Round Stake, Square Stake, Bick Iron Stake, Blow Horn Stake, Electric Soldering Gun, Circular saw machine, Workbenches, Bench drilling machine, Bench grinder, Leg vice, Power hacksaw machine, Arc welding machine.

Metrology & Measurements Lab:

-

9Autocollimator, Optical Profile Projector, Calibration of thermo couple, Load Cell, LVDT Amplifier, Gear tooth Vernier Caliper ,Bore dial gauge – 18X35mm, Bore dial gauge – 35X60mm, Tool Makers Microscope, Dead Weight Pressure Gauge, Floating Carriage Micrometer, Comparators, Thread Micrometer, Vernier Caliper, Micrometer, Strain Gauge, Dial Indicator.

CAD & CAM/Automation Lab:

-

10CNC Lathe, Pick and Place Robot, Computers Softwares (ANSYS, SOLID EDGE, CNC Programming, MATLAB).